Automotive & Other Industries

Leveraging our knowledge and experience we can offer solutions for many other industries including the automotive, mass transit and on highway sectors

Driving our Competencies & Capabilities Further

GKN Wheels & Structures competencies developed in the automotive and off-highway markets are becoming increasingly relevant across other industries. With a long history as an established Tier 1 supplier to the automotive industry, GKN Structures is diversifying to provide services to the off-highway, defence and truck industries. Whilst we are growing our portfolio of customers outside of the automotive sector, they will still benefit from our world-class automotive accredited facilities and compliance to the relevant automotive standards of work e.g. full TS16949 compliance.

Automotive Modules & Systems

GKN Structures has built an outstanding reputation for excellence and reliability in the design, development and manufacture of automotive components, suspension, body and structural systems for major OEM’s. Capabilities include:

- Engineered underbody structural components

- Sub-frames

- Undertrays

- Suspension links

- Ladder frame chassis

- Steel & aluminium expertise

- High volume mainstream to low volume market-leading specialist OEM customers

- Build to print & GKN engineered solutions

- Multi-stage press lines

- Blanking lines

- Robotic welding and laser inspection

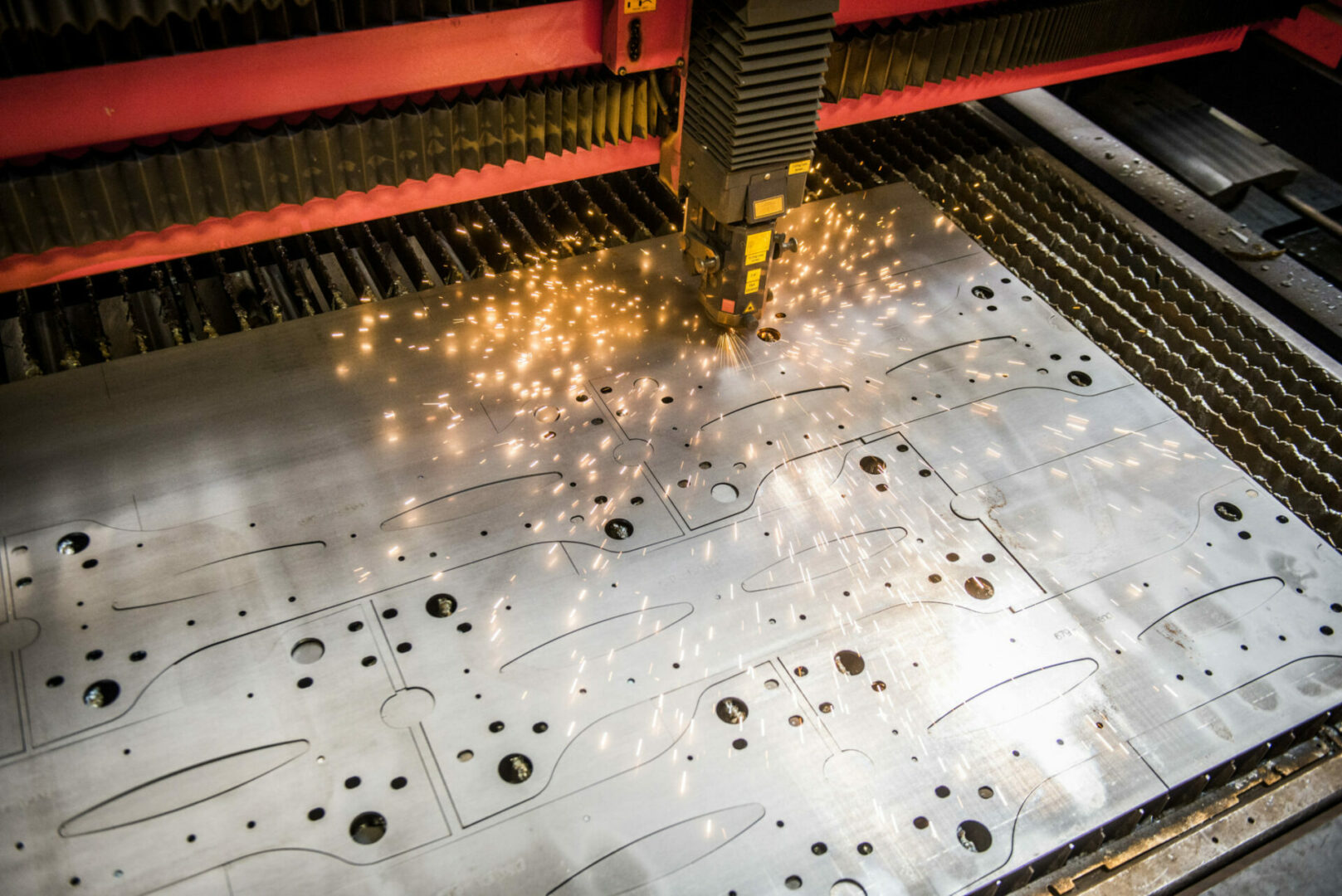

Non-automotive lower volume processing

Expertise in automation for both press and robotic welding means at GKN Structures we are equipped to apply this knowledge and technology to your solutions. With investment across the site in lasers, press brake and e-coat and paint quality. Capabilities include:

- Heavy gauge laser, brake press & welded steel structures

- Robotic welding

- Resistance, spot and projection welding

- Dedicated robotic cells and flow lines

- Full chassis to smaller structural assemblies

- Large capacity envelope shot blast facilities

- Automotive standard E-coat

Expertise in Materials

GKN Structures is today working closely with customers to reduce the weight of new products through intelligent design and the use of appropriate materials to help reduce transport emissions, and this part of the process is becoming more relevant as consumers seek greener vehicles.

- Structural design & test consultancy services

- In-house prototyping

Key product features and benefits:

- Extensive R&D facilities and complete in-house testing

- Automotive standard corrosion protection by electro coat primer, large capacity facilities

- Carbon composite capability under development

From Concept to Design and Test

GKN Structures has the proven capability to support complete model programs from concept through to design and test. With its specialist in-house Test Centre, based in Telford, we can offer vehicle designers a unique service to test from small components to comprehensive, whole vehicles assessments. Comprehensive analysis and reporting can be provided following a range of tests, from extensive road and real-life simulation, to individual components.

The modular design of the test centre and its equipment allows for easy adaption to meet a broad range of requirements.

Find out more here

Be the first to find out about new releases, offers and more from GKN Wheels & Structures...